In manufacturing small improvements in efficiency are often overlooked, either because larger inefficiencies take precedence or due to being seen as too expensive to implement.

This second case is why MoMaVi was developed. With powerful functionality and a much lower barrier to entry, MoMaVi allows incremental gains in efficiency and traceability throughout the manufacturing process. Where more traditional solutions will incorporate an industrial camera and processing unit or a Smart Camera with the processor built in, MoMaVi is an app that can run on an Android Smartphone, turning it into a smart camera in its own right.

The application

There are a number of features that need to be verified during the assembly of the engine and in this stage the connecting rods and caps are checked and verified. Before MoMaVi verification of these parts was done visually by a technician. While an operator could check the features at a glance, there was no recording of metrics or traceability. In these days of big data all new sources of information can be used to ensure quality, increase efficiency, implement predictive maintenance and drive innovation.

The Solution

While MoMaVi supports all of the functionality needed to verify all of the features, a custom application would provide easier implementation and use. The efficiency is also increased with the custom application by combining the different functions to reduce the number of images needed to complete all of the necessary processing.

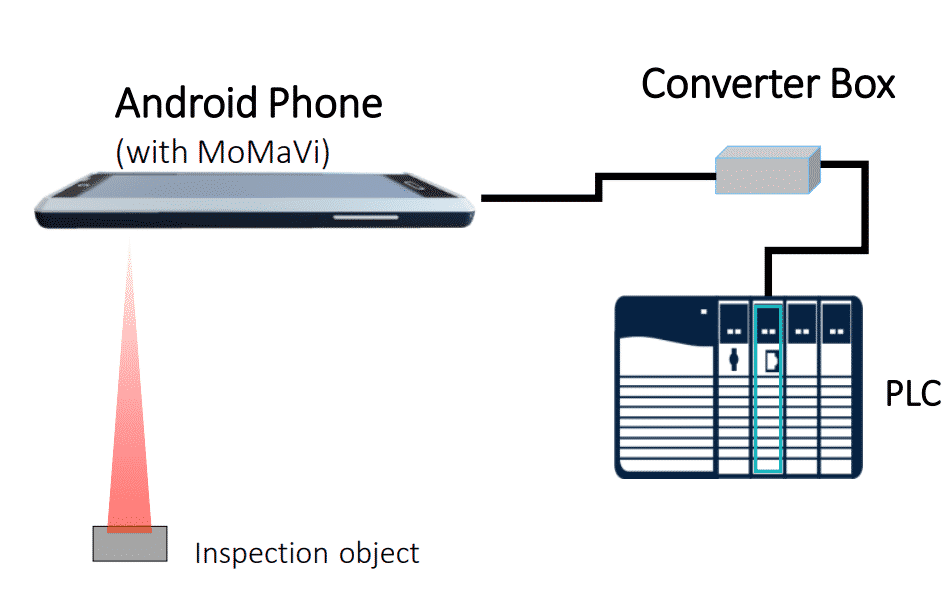

The system needs to be compatible with other systems in use at the factory including interfacing with an already existing PLC. The USB2LAN converter with integrated charging allows the MoMaVi system to keep the smartphone batteries charged and connect to the PLC via LAN.

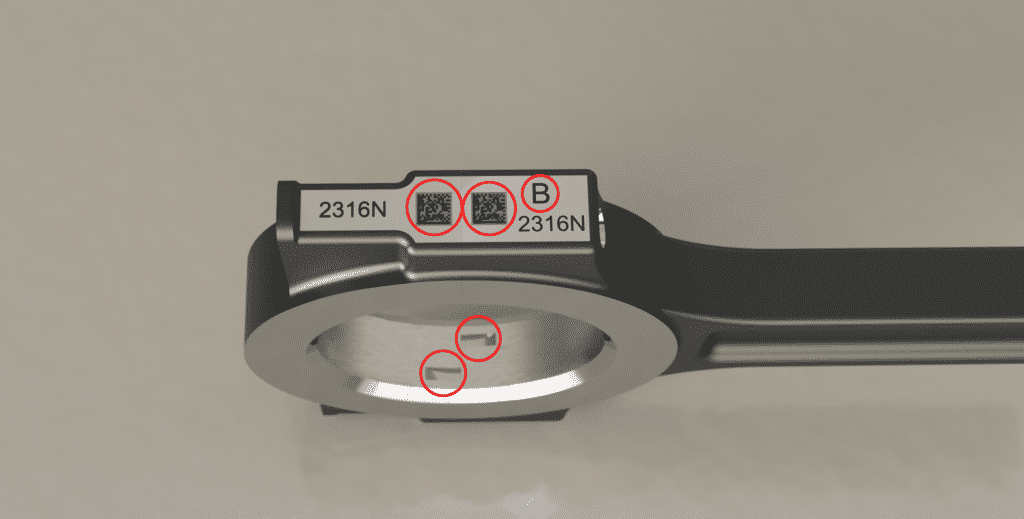

To verify the matching pairs of rod and cap the Data Matrix codes are read using the code reading function. If both the connecting rod and the have identical information, the test is passed.

To read the letter that designates the position of the rod Optical Character Recognition(OCR) was used.

Finally blob analysis is used to verify the presence of the bearing tang notches.

Typically assembly stations are well lit and additional lighting is not needed, helping to keep the cost of the system down. If, by testing, it is determined that external illumination is needed, a standard ring light attached to the smartphone holder and controlled by the app will provide the illumination necessary to properly image all of the necessary features.

Why should you consider MoMaVi and an Android Smartphone for your Machine Vision needs?

The smartphone market moves fast. Every year Smartphone manufacturers release new models with better specifications. New Smartphones have large pixel count image sensors, high quality optics, fast CPUs and copious amounts of memory. The research and development put into the phone industry eclipses that of machine vision by orders of magnitude. Considering the performance, capability and price, mobile machine vision is an attractive option.

Contact FOVEOS and see how MoMaVi can improve efficiency, reduce errors and enable traceability in your assembly lines.